Our primary research interests include experimental micro/nanomechanics, nanocomposites, advanced/additive manufacturing, nanoscale adhesion and interfaces, bio-inspired complex and hybrid systems, and nanoelectromechanical systems (NEMS).

Manufacturing and Mechanical Characterization of BNNT and CNT-reinforced Nanocomposites

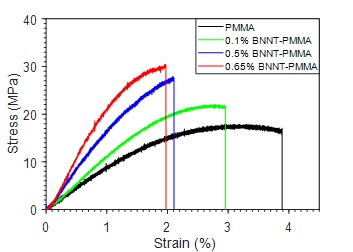

investigating the manufacturing of carbon and boron nitride nanotubes (CNTs and BNNTs) reinforced nanocomposites with a wide selection of matrix materials (including polymers, metals, and ceramics) and investigated their mechanical properties. Nanotube-reinforced polymer nanocomposite microfibers were manufactured using electrospinning techniques and their mechanical properties were investigated using in situ Raman micromechanical characterization techniques. The results provide insights into the interfacial load transfer inside the bulk nanocomposites and the reinforcing mechanism of nanotubes. We are also investigating the manufacturing and mechanical properties of nanotube-reinforced metal nanocomposites.

|

The measured stress-strain curves of individual PMMA and BNNT-PMMA microfibers. |

References:

1. N. Anjum, O.Q. Alsmairat, Z.-H. Liu, C. Park, C.C. Fay, C.-H. Ke, "Mechanical Characterization of Electrospun Boron Nitride Nanotube-Reinforced Polymer Nanocomposite Microfibers,", Journal of Materials Research, 2022. (pdf)

2. O.Q. Alsmairat, F.-L. Gou, C.M. Dmuchowski1, P.R. Chiarot, C. Park, R.N. Miles, C.-H. Ke, "Quantifying the Interfacial Load Transfer in Electrospun Carbon Nanotube Polymer Nanocomposite Microfibers by Using in situ Raman Micromechanical Characterization Techniques," Journal of Physics D: Applied Physics, Vol. 53, pp. 365302, 2020. (pdf)

Interfacial Mechanical Properties of BNNT and CNT-reinforced Polymer Nanocomposites

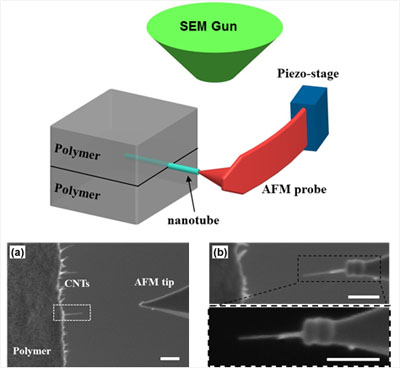

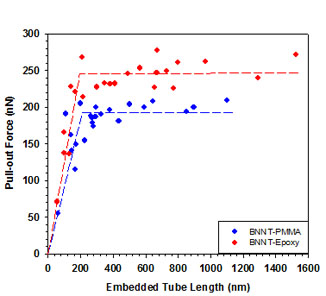

The quest for light, strong and durable composite materials is of importance for a number of industries, such as the aerospace and automobile industries. The interfacial load transfer capacity of nanofiller-polymer interfaces plays a critical role in the bulk performance of fiber-reinforced polymer nanocomposites, and thus a primary factor in the selection of reinforcing nanofiller materials. We investigted the interfacial load transfer between individual carbon and boron nitride nanotubes (CNTs and BNNTs) and polymer matrices using in situ electron microscopy nanomechanical single-tube pull-out technqiues. Our studies reveal shear lag effects on the tube-polymer interface. The nanomechanical measurements show that the shear strengths of BNNT-epoxy and BNNT-poly(methyl methacrylate) (PMMA) interfaces are higher than those of the comparable interfaces formed with CNTs. The findings of the extraordinary mechanical strength of BNNT-polymer interfaces suggest that BNNTs are excellent reinforcing nanofiller materials for light-weight and high-strength polymer nanocomposites.

In situ electron microscopy nanomechanical single-tube pull-out scheme and selected snapshots of one single-tube pull-out measuremnt. . |

The dependence of the pull-out load on the embeded tube length for BNNT-epoxy and BNNT-PMMA interfaces. Similar trends are also observed for CNT-polymer interfaces. |

References:

1. X.-M. Chen, L.-Y. Zhang, C. Park, C.C. Fay, X.-Q. Wang and C.-H. Ke, “Mechanical Strength of Boron Nitride Nanotube-Polymer Interfaces,” Applied Physics Letters, Vol. 107, 2015. (pdf)

2. X.-M. Chen, L.-Y. Zhang, M. Zheng, C. Park, X.-Q. Wang and C.-H. Ke, "Quantitative Nanomechanical Charaterization of the van der Waals Interfaces between Carbon Nanotubes and Epoxy", Carbon, Vol. 82, pp. 214-228, 2015. (pdf)

3. X.-M. Chen, M. Zheng, C. Park, C.-H. Ke,"Direct Measurements of the Mechanical Strength of Carbon Nanotube-Poly(methyl methacrylate) Interfaces,” Small, Vol.9, pp.3345–3351, 2013.(pdf)

Mechancial Properties of 2D Materials: Bending, Interlayer Shear, Folding and Adhesion

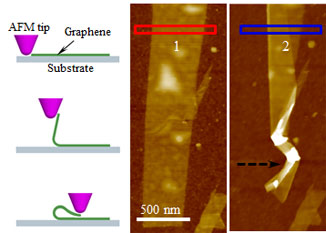

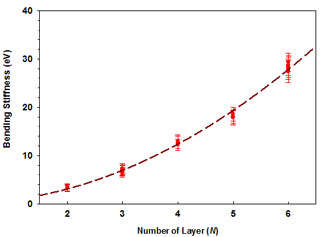

The mechanical properties of graphene are of importance in the pursuit of many of its potential applications, such as graphene-based nanoelectromechanical resonators and switches, and programmable building blocks or origami. We investigate the bending, interlayer shear, and adhesion properties of graphene by using atomic force microscopy in conjuction with continnum mechanical modeling and molecular dynamics simualtions. Our studies focus on examining the self-folding of few-layer graphene on a flat substrate. The results reveal that the bending stiffness of 2-6 layers graphene follows a square-power relationship with its thickness.The research findings show that the weak interlayer shear interaction has a substantial stiffening effect on the bending rigidity of multilayer graphene.

Nanomechanical folding of individual graphene sheet into self-folded conformation by atomic force microscopy nanomanipulation techniques. |

The bending stiffness of few-layer graphene based on AFM-measured self-folded graphene. The dotted line is a square-power fitting curve. |

References:

1.X.-M. Chen, C.-L. Yi and C.-H. Ke, "Bending Stiffness and Interlayer Shear Modulus of Few-layer Graphene", Applied Physics Letters, Vol. 106, Art No 101907, 2015. (pdf)

2.X.-M. Chen, L.-Y. Zhang, Y. Zhao, X.-Q Wang, and C.-H. Ke, “Graphene Folding on Flat Substrates,” Journal of Applied Physics, Vol. 116, pp. 164301, 2014. (pdf)

Radial mechanical properties of one-dimensional tubular nanostructures

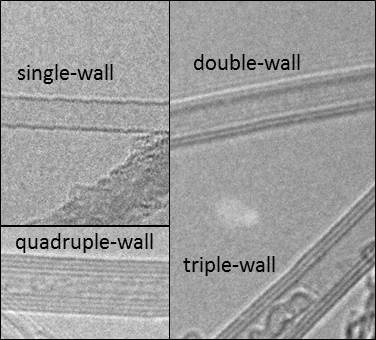

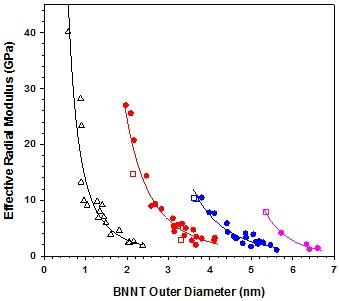

Radial mechanical properties of one-dimensional tubular nanostructures, such as carbon nanotubes and boron-nitride nanotubes, are of great importance to their respective structural, mechanical and electrical properties and applications. The radial rigidity of nanotubes determines their cross-section configurations in the forms of bundles or ropes or when they are in contact with other material surfaces, and has a significant influence on their mechanical deformational behaviors under a variety of loading conditions (e.g. compression, bending and torsion). In addition, radial deformation of nanotubes can greatly influence their electronic structures (e.g. band-gaps) and result in semiconductor-to-metal or metal-to-semiconductor transitions. Our research focuses on characterizing the radial mechanical properties of single- and multi-walled carbon and boron nitride nanotubes and pursuing new approaches of engineering and controlling radial deformation in these nanostructures.

High resolution tranmission electron microscopy images of single- to quadruple-walled boron nitride nanotubes. |

Radial Effective Modulus of single- and multi-walled boron nitride nanotubes |

References:

1. M. Zheng, X.-M. Chen, I.-T. Bae, C.-H. Ke, C. Park, M.W. Smith, K. Jordan, “Radial Mechanical Properties of Single-walled Boron Nitride Nanotubes,” Small, Vol. 8, pp. 116-122, 2012. (pdf)

2. M. Zheng, C.-H. Ke, I.-T. Bae, C. Park, M.W. Smith, K. Jordan, “Radial Elasticity of Multi-walled Boron Nitride Nanotubes,” Nanotechnology, Vol. 23, Art No 095703, 2012. (pdf)

3. M. Zheng, L.-F. Zou, H. Wang, C. Park, C.-H. Ke, "Engineering Radial Deformations in Single-Walled Carbon and Boron Nitride Nanotubes using Ultra-Thin Nano-Membranes," accepted for publication in ACS Nano, 2012.

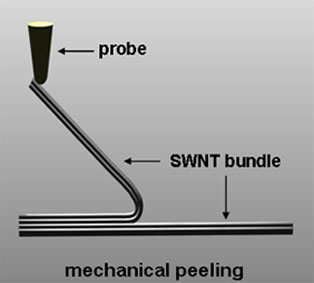

Nanoscale interfacial binding strength and its impact on mechanical deformation of nanostructures

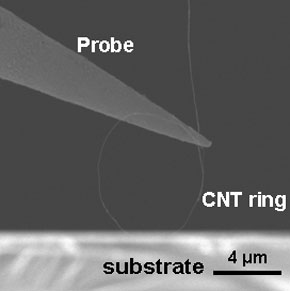

Nanoscale interfacial binding strength between nanostructures (e.g. nanotubes) has significant impact on the mechanical properties of the nanostructures and their applications. Nanoscale experimental characterizing is capable of quantifying the true nanoscale interfacial strength, which is unremarkable affected by a variety of structural imperfections (e.g. defects and contamination. However, the nanoscale dimensions of the nanostructure pose many challenges in the detection of the mechanical response of the nanostructure and the applied load with adequate resolutions. We overcome these challenges by using in situ scanning electron microscopy mechanical characterization scheme to experimentally characterize the interfacial binding strength between nanostructures (e.g. single-walled carbon nanotube bundles) and the influence of nanoscale adhesion strength on the elastic deformation of nanostructures (e.g. carbon nanotube bundles and carbon nanotube rings).

Schematic of quantifying the interfacial binding strength between single-walled carbon nanotubes by in-situ mechanical nano-peeling experiments. |

SEM snapshot of in-situ mechanical pulling a carbon nanotube nano-ring from a Au-coated Silicon substrate. |

References:

1. M. Zheng and C.-H. Ke, “Elastic Deformation of Carbon Nanotube Nano-rings," Small, vol.6, pp.1647- 1655, 2010. (pdf )

2. C.-H. Ke, M. Zheng, I.-T. Bae, G.-W. Zhou, “Adhesion-Driven Buckling of Single-Walled Carbon Nanotube Bundles,” Journal of Applied Physics, Vol.107, Art No 104305, 2010. (pdf)

3. C.-H. Ke, M. Zheng, G.-W. Zhou, W.-L. Cui, N. Pugno, R.N. Miles, “Mechanical Peeling of Free-Standing Single-Walled Carbon Nanotube Bundles,” Small, Vol. 6, pp. 438-445, 2010. (pdf)

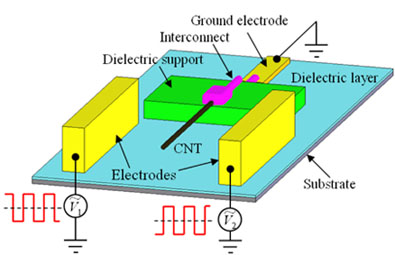

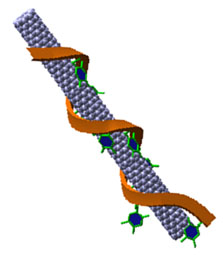

One-dimensional nanostructure-based nanoscale dynamical systems

One-dimensional nanostructure-based nano-resonators possess many extraordinary dynamical characteristics such as extremely high resonant frequency and integration level and low energy consumption, which are currently being pursued for a number of applications, such as ultrasensitive sensor for mass and force detection and detectors for chemical and biomolecule agents, and signal processing. Our group is currently focusing on investigating a novel carbon nanotube-based tunable electromechanical resonator. This resonator adopts a double-side electrostatic actuation scheme and the nanostructure is actuated in the "pull and push" manner. This resonator design has superior resonant frequency tuning capabilities compared with conventional resonator of the single-side actuation scheme and operating in the "pull-only" mode. We are currently investigating the electromechanical dynamics of this resonator using multiphysics modeling, micro/nano-fabrication and in-situ scanning electron microscopy electromechanical characterization techniques. We are also interested in studying the impact of the structural imperfections (e.g. surface contamination) on the dynamics of the nanostructure and studying the dynamical response of nanostructure to the binding of biomolecules (e.g. DNA).

Schematic of a double-sided driven carbon nanotube-based tunable electromechanical nano-resonator for tunable sensor and electronics applications. |

Schematic of detecting single DNA molecules using carbon nanotube-based nano-resonator. |

References:

1. C.-H. Ke, "Resonant Pull-in of a Double-Sided Driven Nanotube-Based Electromechanical Resonator," Journal of Applied Physics, Vol.15, Art No 024301, 2009. (pdf)

2. M. Zheng, K. Eom, and C.-H. Ke, “Calculations of the Resonant Response of Carbon Nanotubes to Binding of DNA,” Journal of Physics D- Applied Physics, Vol. 42, Art No 145408, 2009. (pdf)

Last Updated: 4/10/10